Properties

Physical characteristics vary based on grade but may include:

- HDPE

- Durable

- High impact strength

- Excellent stiffness

- Excellent tensile strength

- Abrasion resistance

- Resistance to stress cracks

- LDPE

- Durable

- Flexible

- Resistance to stress cracks

- Corrosion resistant

Typical Uses

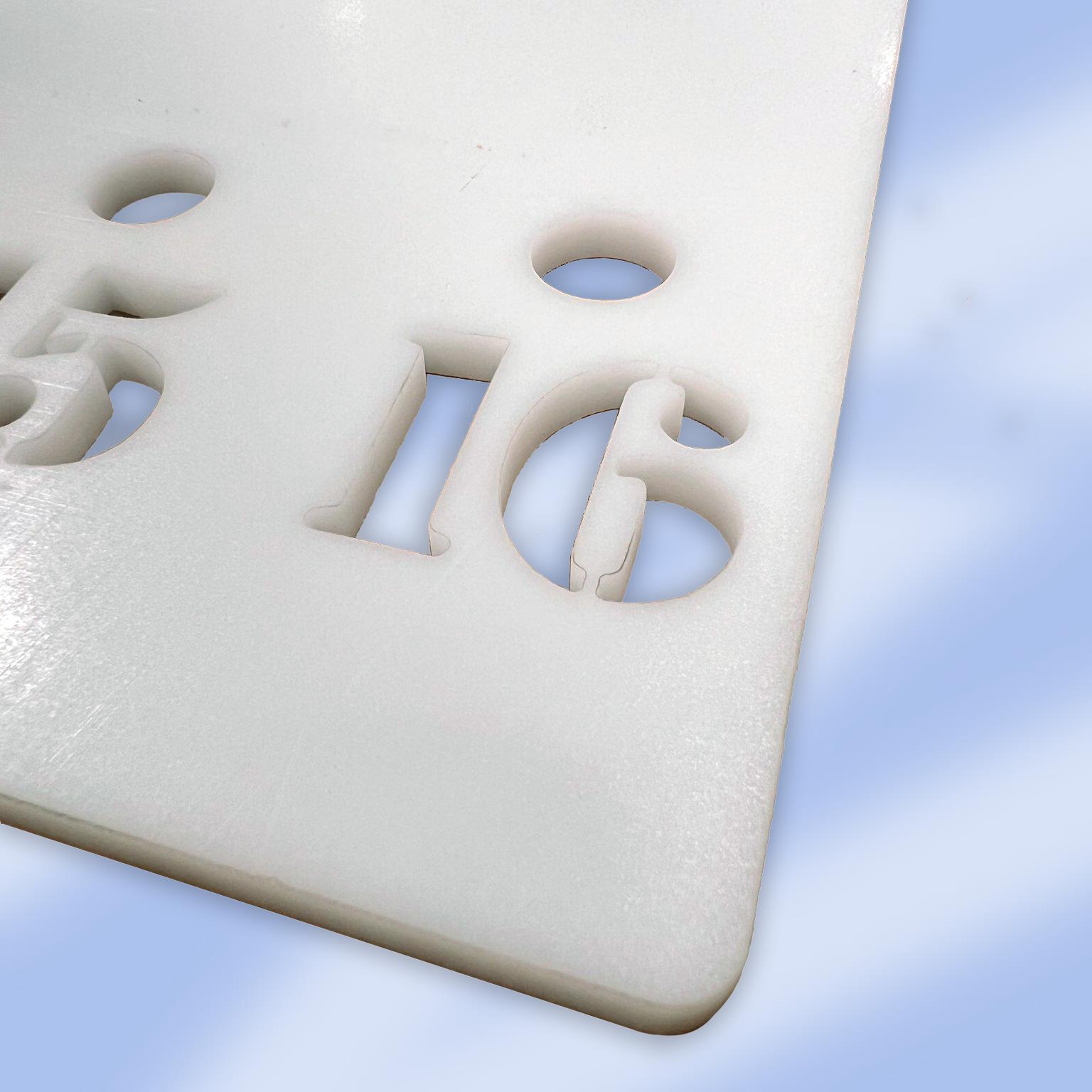

- Cams, washers, shims

- Machined parts

- Rack liners / protectors

- Tank, chute, bin linings

- Cutting boards

|

|

Polyethylene plastic stock shapes

Polyethylene (PE) is available in many different grades making it one of the most widely used plastics. Two of the most common are LDPE (Low-Density Polyethylene ) and HDPE High-Density Polyethylene.

HDPE is a high-impact strength and high-density polyethylene. HDPE has excellent tensile strength, energy absorption, abrasion resistance, and resistance to stress cracks. HDPE has little branching, giving it stronger intermolecular forces and tensile strength than lower-density polyethylene. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and more opaque and can withstand somewhat higher temperatures (120 °C/ 248 °F for short periods, 82.2 °C /180 °F continuously). High-density polyethylene, unlike polypropylene, cannot withstand normally-required autoclaving conditions.

LDPE is a flexible lightweight plastic with good tear resistance, corrosion resistance, it is durable and remains flexible at lower temperatures. LDPE is somewhat translucent in appearance. It is easily machined and FDA compliant grades are used in food applications.

|

|