Properties

- Broadest size range availability

- Good mechanical and electrical properties

- Ideal balance of strength and toughness

- Many grade options: FDA compliant, internally lubricated, and heat stabilized

Typical Uses

- Bushings and bearings

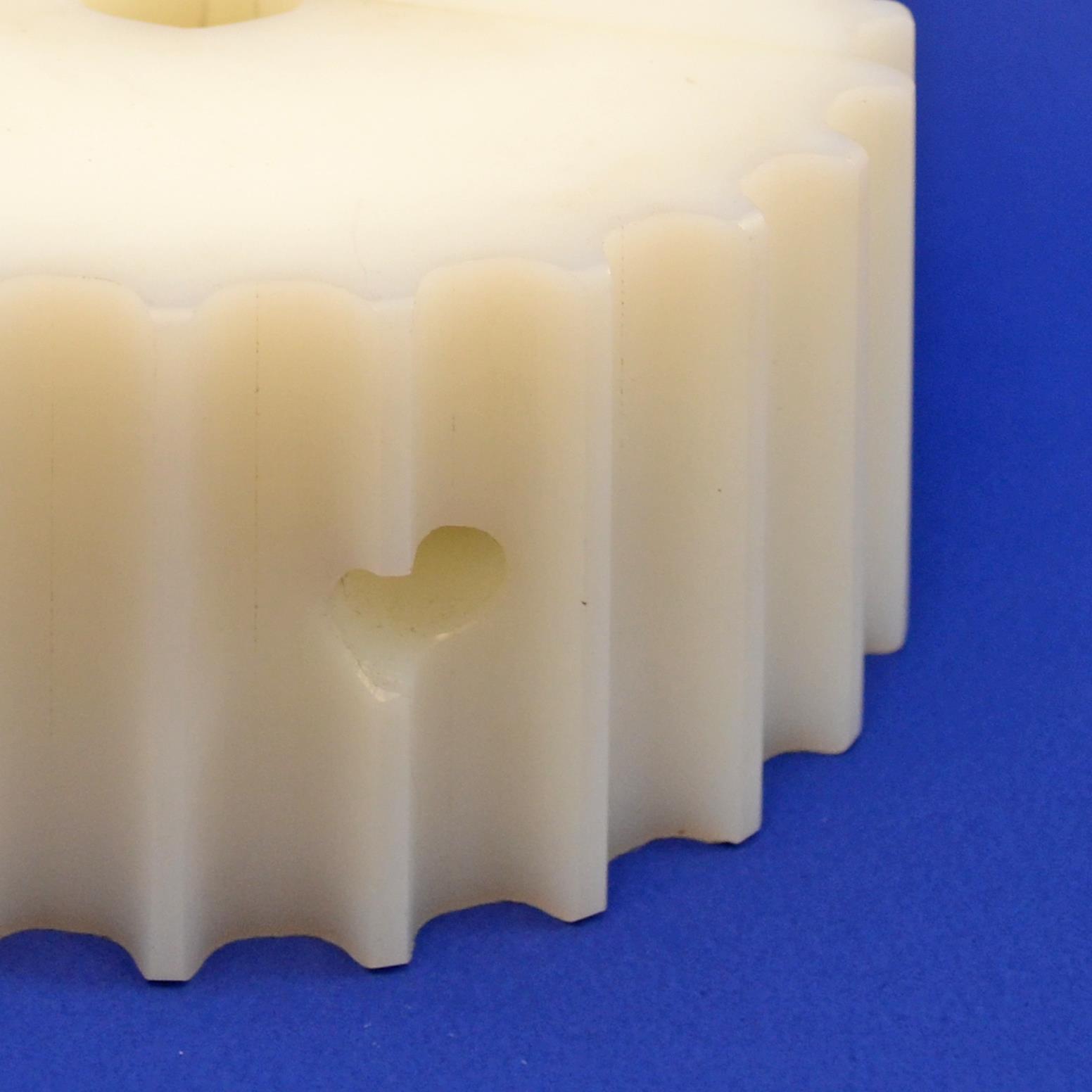

- Gears and sprockets

- Wear rails, pads and strips

- Pulleys and sheaves

- Conveyor wheels and rollers

- Feed screws

- Star wheels

|

|

Extruded Nylon 6/6 Machinable Plastic

Extruded nylon type 6/6 is characterized as having an excellent combination of physical properties including a high melting point, resistance to repeated impacts, low coefficient of friction, and a resistance to abrasion. It has good resistance to fuels, lubricants, and most chemicals, but is attacked by phenols, strong acids, and oxidizing agents.

Nylon is one of the most widely used and versatile thermoplastic resins. Its combination of physical properties and reasonable price make it a favorite choice for numerous applications. Nylons toughness, wear resistance, tensile strength, and lubricity make it a good choice for many mechanical machine parts.

What Is the Difference Between Nylon 6 and Nylon 6/6

the primary difference is in the manufacturing process resulting in some physical property differences. Nylon 6 is a cast material which gives it a slightly lower continuous service temperature rating than Nylon 6/6Nylon 6 can withstand higher combinations of load and speed in bearing applications than 6/6 can. It should also be noted that cast nylons have the highest rate of absorption of all the PA formulations and therefore may not be the best choice in wet environments.

|

|