Properties

- Excellent impact resistance

- Good machinability

- Excellent aesthetic qualities

- Easy to paint and glue

- Good strength and stiffness

- Vacuum formable

- FDA compliant grades

- Low cost

Typical Uses

- Machined prototypes

- Support blocks

- Structural components

- Housing covers

|

|

General grade ABS Sheet

ABS, acrylonitrile-butadiene-styrene, is a low-cost engineering plastic that is easy to machine and fabricate. ABS is an ideal material for structural applications when impact resistance, strength, and stiffness are required. It is widely used for machining pre-production prototypes since it has excellent dimensional stability and is easy to paint and glue. In addition, ABS works very well with the vacuum-forming process.

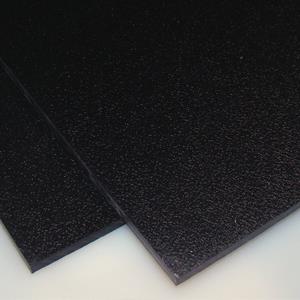

ABS Texture Options

ABS sheet is available in a variety of texture options including:

- Smooth finish both sides

- Haircell one side, smooth one side

- Haricell both sides

What is a Haircell Finish?

Haircell finish is similar to the surface of an orange peel, giving it a little texture vs. a smooth finish.

Alro Plastics stocks ABS in a variety of thicknesses as well as a few different colors. This product can also be cut-to-size on the CNC Saws and machined to print on the CNC Routers or Waterjet cutter.

Trade Names

This product is also known as Tecaran®

|

|